Configurable Chassis and Customization Options

- Configurable Chassis

- Custom Server Chassis

- Custom Storage Chassis

- Custom Military Chassis

- Custom Rugged Computer Chassis

- Custom Industrial Computer Enclosures

- Custom Rackmount Enclosures

- Custom Kits & Brackets

- Branding

- Aluminum Extrusion

- Plastic Injection

- Display Frame / Enclosures

- Custom Faceplates / Bezels

- Custom PCB Design

- Die Casting

- Laser Cutting

- CNC

- Mock up

- 3D Printing

- Services

- Custom Cables

- Special Order

- Under Development

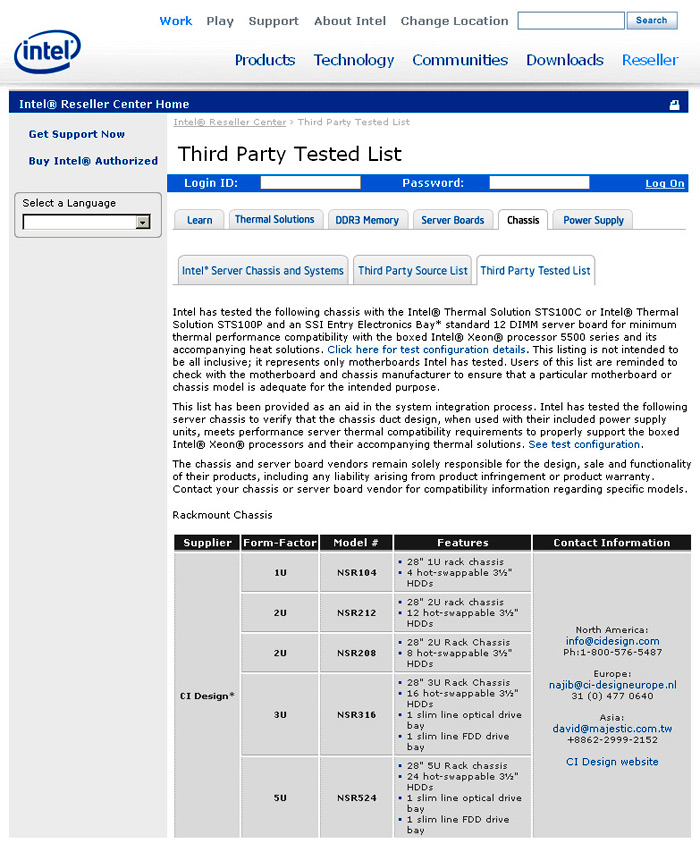

- Intel Validation

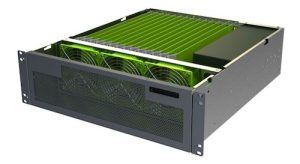

Configurable Chassis

- Cooling Systems: Custom air or liquid cooling solutions.

- Power Configuration: Various wattages and redundant power options.

- Materials and Design: Different materials (such as aluminum alloy, stainless steel) and custom exterior designs.

- Internal Structure: Adjustments for different hardware configurations, such as hard drive bays, motherboard trays, and expansion card slots.

Designing a custom chassis requires considering specific user needs, including space constraints, performance requirements, and budget, to provide the most suitable solution.

Custom Server Chassis

Goto Server Protfolio →

Goto Custom Server Chassis →

- Build a system that works under your specific conditions

- Compatibility with specific motherboards

- High-Performance PCB backplane integration

- Thermal and airflow design built to your specifications

- Interface connections compatible throughout the entire system

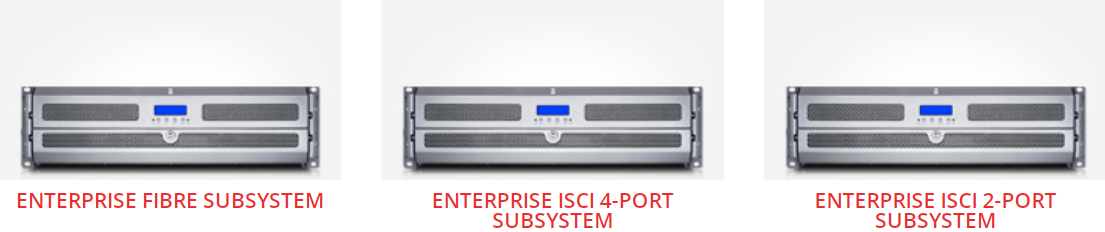

Custom Storage

Goto Storage Portfolio →

Goto Custom Storage Chassis →

- Integration with current systems

- Expansion and upgrade of current storage or server solutions

- Increased system-wide compatibility

- Network solutions built specifically for your business

Custom Military Chassis

Goto Military Chassis Portfolio →

Goto Custom Military Computer Chassis →

Get a solution that will not only provide the best protection and performance for your virtual environment, but that is also specifically engineered for your industry:

- Lighter, aluminum-based chassis enclosures for rugged vehicles or weight-sensitive aeronautics

- Meets MIL Specifications

- Enhanced Design for higher EMI and ESD Protection

- Power Cord Retention Bracket

- Lightweight Material

- Dynamic Shock & Vibration Resistant Design

Custom Rugged Computer Chassis

Goto Rugged Computer Chassis →

Whether you need to create space or add protection from the elements for your computer system, a customized chassis is a trusted solution proven to provide beneficial computer support for any model. Custom rugged computer chassis designs feature durable materials to protect essential computer components. These designs feature customized safeguards while traveling with sophisticated computer systems. Custom chassis designs are made to meet the security needs of digital elements housed within the design. The designs, trusted by military and industrial fields, provide maximum safety and reliability. To ensure the chassis meets requirements it is made with careful precision according to computer specifications.

Custom Industrial Computer Enclosure

Goto Custom Industrial Computer Enclosure →

A custom industrial computer enclosure is a great investment for any computer system used in industrial environments. Work with expert computer enclosure designers to create the best solution for your industrial equipment. These enclosures feature quality materials made to withstand dust, humidity, and daily activity. Enclosures are available in all sizes while being created to ensure security, safety, and functionality of your equipment. Custom designs manufactured meet regulation standards for industrial environments.

Custom Rackmount Enclosure

Custom rackmount enclosures are easy to create for any computer system. The designs are custom made according to computer specifications.

Rackmounts feature designs created by expert CAD designers. Your design ideas of any kind are incorporated into the final product. Standard size configurations are available with customized design options. Enclosures feature cut-outs with pre-drilled openings, so your hardware is ready to use after assembly. Partitions, brackets, and backplanes are also incorporated along with other metal mechanisms. Advanced technology such as spot welding provides seamless assembly and professional presentation. Enclosures are finished with unique powder coating for functionality enhancement.

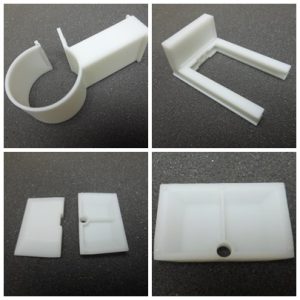

KITS & BRACKETS

- Bracket Kits

Create a solution-based set of brackets. - Custom Individual Brackets

Create independent bracket solutions to your specifications. Mix and match industry standards, or create something completely new. - Standard Individual Brackets

Create independent bracket solutions based on industry standards.

BRANDING & CIS

Branding

Branding refers to the image and reputation of a company or product. A brand is more than just a logo or name; it is a combination of elements that evoke specific values, emotions, and expectations in consumers. Successful branding can build consumer loyalty and help a company stand out in the market.

Corporate Identity System (CIS)

Corporate Identity System (CIS) is a unified system used by a company to express its brand image and values. CIS reinforces brand image through consistent visual and linguistic elements, making the company recognizable and consistent in the market.

Branding and the Corporate Identity System (CIS) are closely intertwined. Branding shapes the overall image and values of a company, while CIS provides the concrete tools to achieve this image and value. Through consistent visual, behavioral, and communication elements, a company can establish a strong brand identity in the market, enhancing consumer trust and loyalty.

ALUMINUM EXTRUSION

An aluminum extrusion service is a customization option that includes shaping materials such as metals or aluminum using a unique shaping process. The result includes the creation of a long aluminum piece made with a special shape at the opening. The process is a trusted solution by many industries. It includes the ability to create different shapes and colors featuring elongated pieces of aluminum. The pieces can be finished with color paint and fabricated for project needs. The aluminum can be joined by adhesives, soldering, welding, drilling, bending, and so on. Architectural and standard shapes are available, and they are recyclable and re-melted.

Plastic Injection

Plastic injection service assists in mass production of parts and materials needed in large volumes. The process includes using a mold and filling it with plastic material. The mold is made of metal, and the plastic filled in the mold is small pellets made of resin injected after heat compression into the mold. The process varies based on types of products or parts made based on size and dimension. The process is cost-effective with options based on quantity and budget. The plastic injection may include prototyping processes or fulfilling the need on-demand. Designs are reviewed in close detail before the process is completed to ensure molding ability, appearance, efficient production time, and customer satisfaction.

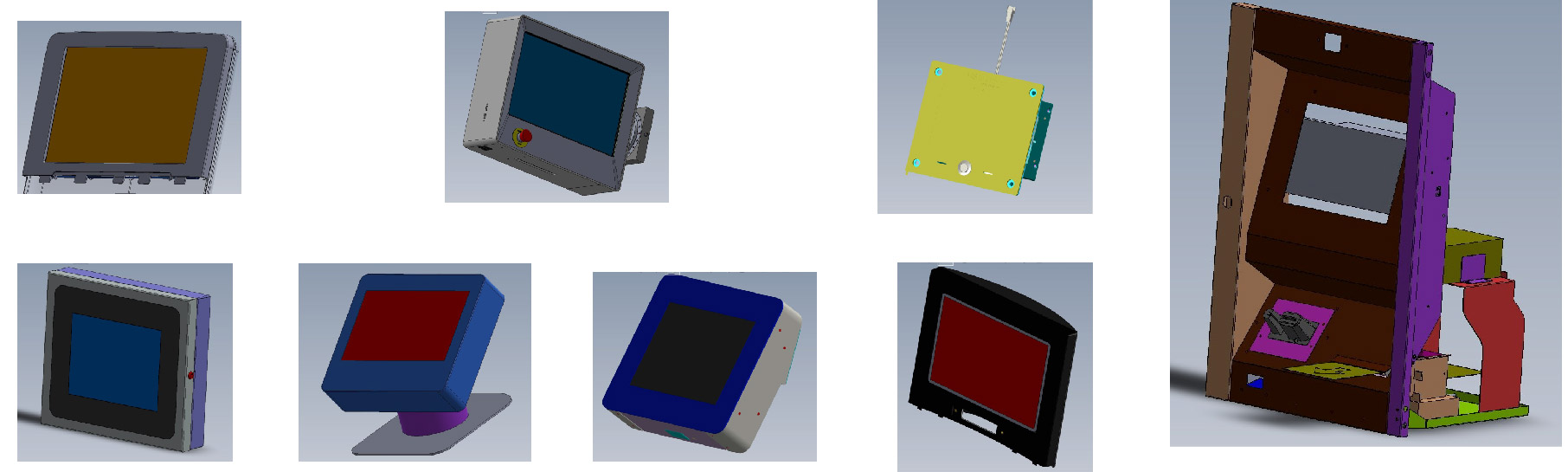

Custom Display Frame / Enclosures

A custom display frame or enclosure is a specially designed casing or housing used to showcase and protect various items, such as artwork, electronic displays, collectibles, or other valuable objects. These frames or enclosures can be tailored to meet specific aesthetic, functional, and environmental requirements.

Components and Features:

- Materials:

- Wood: Offers a classic and elegant look, suitable for traditional and high-end displays.

- Metal: Provides a modern and industrial aesthetic, often used for durability and sleek design.

- Plastic: Versatile and lightweight, ideal for various styles and budget-friendly options.

- Acrylic: Used for the front cover to provide clear visibility and protection against dust and damage.

- Design Customization:

- Size and Shape: Customizable to fit the exact dimensions of the item being displayed.

- Color and Finish: Available in a wide range of colors and finishes to match the décor and style.

- Mounting Options: Can be designed for wall mounting, tabletop display, or freestanding structures.

- Protective Features:

- UV Protection: Special coatings or glass to protect against harmful ultraviolet rays, preserving the item’s integrity and color.

- Security Locks: Integrated locks or tamper-proof features for added security.

- Environmental Controls: Options for humidity and temperature control for sensitive items.

CUSTOM FACEPLATER / BEZEL

Goto Bezel Portfolio →

Goto Custom Faceplate / Bezel →

BEZELS: THE FRONT DOOR

Customizing the bezel door to any unit is key to creating brand awareness for any IT product line. At Ci Design, we offer more than 25 years of trusted OEM & ODM experience to help you define this awareness at the enterprise level.

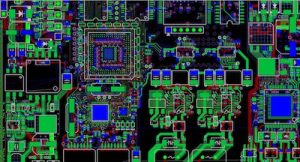

PCB DESIGN

Print circuit board (PCB) design service options ensure your design needs are addressed efficiently and professionally. Services available meet your needs by providing flexible options for prototypes whether new or existing. Experts provide the support your design needs by assessing and evaluating your interests. Services provided assist with develop of applications including consumer electronics of high volume and multi-gigabit solutions. Designs created for applications come from hand drawings or digital concepts with desired measurement components. These designs ensure customers get the results they want with the performance they need.

DIE CASTING

Die casting is a detailed process providing customization to metal materials. The process includes pouring melted metal elements into molds made of steel. The molds help set the material into a solid metal or parts. There are different types of dies, aka molds used based on the type of raw material used in the process to create the mold. Die casting is a prime manufacturing process used to create distinguished metal parts with smooth or sharp edges.While the process offers options for creating customized parts or pieces for equipment needs, it is a cost-effective option when parts are needed in bulk or require mass production.

LASER CUTTING

Laser cutting is a cutting process that can be used to cut different thicknesses of metal and non-metal materials.

The polymerized laser beam is the basis of this technology. After the laser hits the material accurately, the material is heated to melt or evaporate to achieve the cutting purpose

CNC

The high precision, automation, versatility, and intelligence of CNC technology make it an indispensable tool in modern manufacturing. Whether for mass production or customized machining, CNC machines offer excellent performance and flexibility, significantly enhancing production efficiency and product quality.

MOCK UP

Creating a mock-up before product development offers numerous advantages, including visualizing design concepts, improving design and functionality, reducing risks and costs, enhancing team collaboration, conducting market validation, and increasing decision-making confidence. By testing and optimizing the early model, the final product is more likely to meet user needs and market expectations, increasing the chances of product success.

3D PRINTING

3D printing is an additive manufacturing technology that creates three-dimensional objects by adding material layer by layer. This technology can use various materials such as plastics, metals, ceramics, and resins to produce complex designs and structures.

Main Advantages

- Rapid Prototyping

- High Design Freedom

- Reduced Waste

- Lower Production Costs

- Customized Production

Services

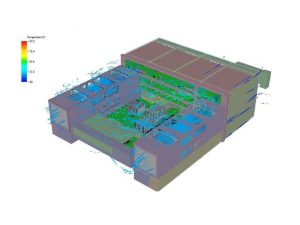

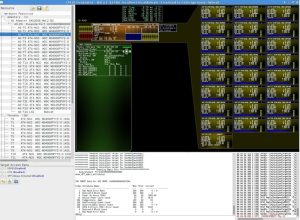

Thermal simulation

Faster way to check the design closely to the actual prototype

CRC test

Precise process to make your product better

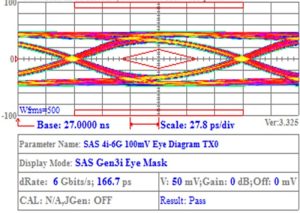

EYE DIAGRAM

Make sure the accuracy of signal Integrity

Cable series

Custom Cable Services:

- Customized to Needs: Cables can be customized in terms of length, color, connector type, and shielding according to specific customer requirements.

- Branding and Labeling: Custom branding and labeling services are available to enhance product recognition and professionalism.

- Professional Advice: Provide professional technical support and advice to help customers choose the best cable solutions.

SPECIAL ORDER

- Customized Design:

- Provide custom-designed chassis solutions based on client specifications and requirements.

- Offer flexible material options such as aluminum alloys, steel, or high-grade plastics to achieve desired aesthetics, durability, and thermal performance.

- Functional Design:

- Design chassis with specific functionalities tailored to client needs, such as multiple expansion slots, support for water cooling systems, fan configurations, and adjustable power supply units.

- Provide customization options suitable for various application scenarios, including industrial control, high-performance computing, media servers, etc.

- Production and Manufacturing:

- Utilize advanced production facilities and technologies capable of handling small to large batch orders efficiently.

- Ensure quality control and compliance with relevant product standards and certification requirements.

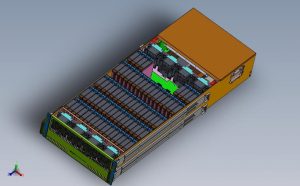

Under Development

We are currently developing a new server solution designed to meet the high-performance and reliability demands of AI environments.

These server chassis will integrate the latest technologies to deliver outstanding performance and exceptional security.

Our engineering team is working diligently to ensure that the new product meets the strictest quality standards and your expectations.