Die Casting

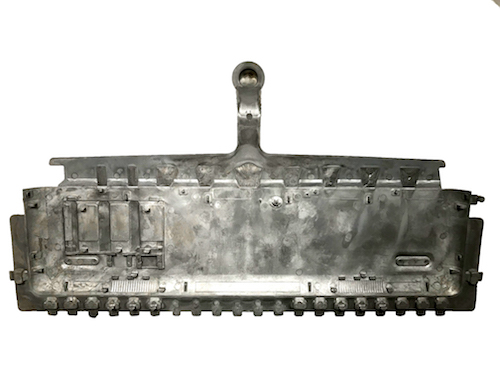

Die casting is a detailed process providing customization to metal materials. The process includes pouring melted metal elements into molds made of steel. The molds help set the material into a solid metal or parts. There are different types of dies, aka molds used based on the type of raw material used in the process to create the mold. Die casting is a prime manufacturing process used to create distinguished metal parts with smooth or sharp edges.While the process offers options for creating customized parts or pieces for equipment needs, it is a cost-effective option when parts are needed in bulk or require mass production.

When using raw materials, the process makes it easy for product parts to be created meeting specific dimensions, angles, and other essential features. Casting allows for any shape to be created while including elements that ensure the process is completed correctly. Die casting also allows for parts to be joined together if the assembly is needed. The process helps metals gain higher toleration levels making a strong and finished part. Scrape materials are minimized, and production of many types of parts is completed quickly and thoroughly thanks to technology advancements assisting in the regulation of the casting process.