Products & Services

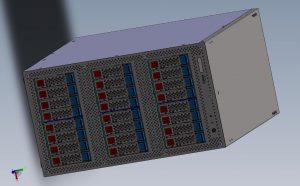

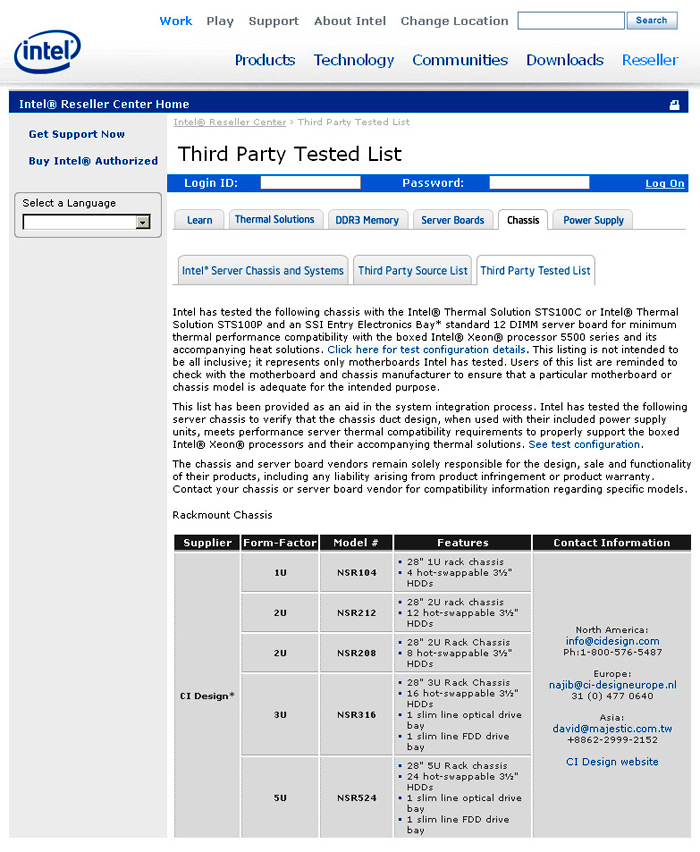

Configurable Chassis

Standard chassis for quick and easy configuration of your choice.

From 1U to 8U, towers can be configured to suit your needs.

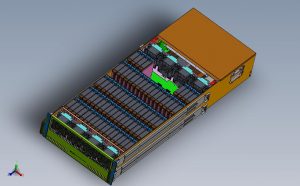

Custom Chassis

- Build a system that works under your specific conditions

- Compatibility with specific motherboards

- High-Performance PCB backplane integration

- Improved and customized power supply

Goto SERVER CHASSIS→

- Integration with current systems

- Expansion and upgrade of current storage

- Increased system-wide compatibility

- Network solutions built specifically for your business

Goto STROAGE CHASSIS→

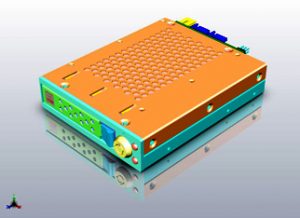

- Meets MIL Specifications

- Enhanced Design for higher EMI and ESD Protection

- Lightweight Material

- Dynamic Shock & Vibration Resistant Design

Goto MILITARY CHASSIS→

- Shock and vibration

- Temperature and humidity

- Corrosion and abrasion

- Minimal size, weight, and power (SWaP)

Goto RUGGED COMPUTER CHASSIS→

- Forced air, liquid, and conduction cooling

- Expansion card retention

- Enhanced EMI filtering and gasket

- Enhanced environmental protection

Goto INDUSTRIAL COMPUTER ENCLOSURE→

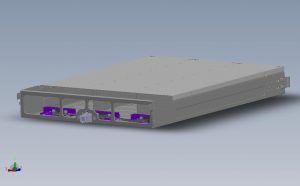

Custom rackmount enclosures are easy to create for any computer system. The designs are custom made according to computer specifications. Rackmounts feature designs created by expert CAD designers. Your design ideas of any kind are incorporated into the final product. Standard size configurations are available with customized design options. Enclosures feature cut-outs with pre-drilled openings, so your hardware is ready to use after assembly. Partitions, brackets, and backplanes are also incorporated along with other metal mechanisms. Advanced technology such as spot welding provides seamless assembly and professional presentation. Enclosures are finished with unique powder coating for functionality enhancement.

Custom designs for rackmount enclosures take a few days to build on average. Built using durable and sturdy materials, customizing your enclosure becomes an important investment ensuring reliability and effectiveness. Many material options are available based on security and protections. The designing process includes configuring the best height and width accommodations, depth, and needs for hardware accessories. Detailed manufacturing processes ensure quality results for your design. Designs created will meet required regulations to ensure safety compliance and satisfaction guaranteed. Discuss your needs with a design expert to learn more about how your computer system benefits from custom rackmount enclosure designs.

Goto RACKMOUNT ENCLOSURES→

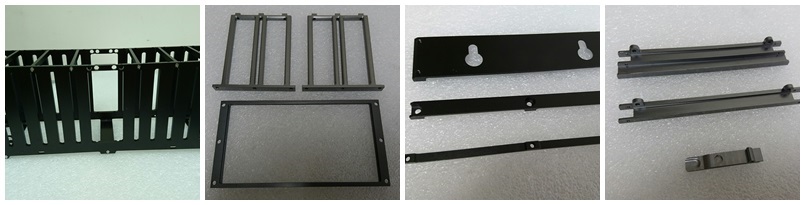

Custom Kits & Brackets

- Brackets for standard rackmount dimensions from 1U and up

- Brackets for tower-style, portable-style, or custom-shaped enclosures

- Solution-based bracket sets

- We take both small and large volume orders depending on specifications

As a custom OEM & ODM solutions provider, Ci Design is capable of supporting virtually any custom kit & bracket design for any system. To name a few:

- Computer Mount Brackets

- Workstation Mounts

- PC Mounts

- Computer Desktop Mounts

Goto Custom Kits & Brackets→

BRANDING

Bring us your ideas, and we’ll create a solution that sticks to your styles and your company image. We offer a wide range of branding options to help you establish a unique presence in your industry, including:

- Metallic materials such as aluminum, sheet metal, stainless steel, and titanium

- High-quality plastics such as acrylic and fiberglass

- Brushed and polished finishes

- Several painting options, from Liquid Wet Paints to Powder Coating, customized specifically to your Pantone colors

- Special adhesives, pressure-sensitive labeling & tagging options

- Silk Screening, Engraving, & Pad Printing

- Aesthetic flexibility and an experienced design team to help you customize your Faceplate Bezel

Goto BRANDING→

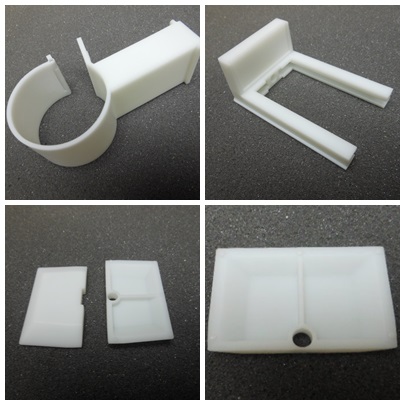

PLASTIC INJECTION

Plastic injection service assists in mass production of parts and materials needed in large volumes. The process includes using a mold and filling it with plastic material. The mold is made of metal, and the plastic filled in the mold is small pellets made of resin injected after heat compression into the mold. The process varies based on types of products or parts made based on size and dimension. The process is cost-effective with options based on quantity and budget. The plastic injection may include prototyping processes or fulfilling the need on-demand. Designs are reviewed in close detail before the process is completed to ensure molding ability, appearance, efficient production time, and customer satisfaction.

Goto PLASTIC INJECTION→

ALUMINUM EXTRUSION

An aluminum extrusion service is a customization option that includes shaping materials such as metals or aluminum using a unique shaping process. The result includes the creation of a long aluminum piece made with a special shape at the opening. The process is a trusted solution by many industries. It includes the ability to create different shapes and colors featuring elongated pieces of aluminum. The pieces can be finished with color paint and fabricated for project needs. The aluminum can be joined by adhesives, soldering, welding, drilling, bending, and so on. Architectural and standard shapes are available, and they are recyclable and re-melted.

Goto ALUMINUM EXTRUSION→

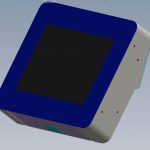

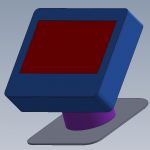

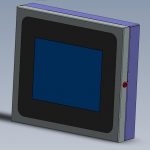

Display Frame / Enclosures

Customized displays are designed to respond to a variety of environments, including direct sunlight, partial sunlight and shade. In addition, they provide protection from rain, snow and other elements.

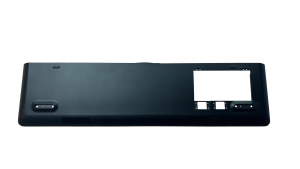

Faceplate/Bezels

- Customized Bezel for Rackmount/Desktop Systems

- Choose from Metal, Aluminum, or Pastic Materials

- Differentiate yourself from the competition

- Flexibility for all your custom branding need

Goto Faceplate/Bezels →

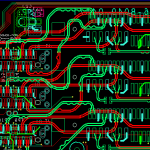

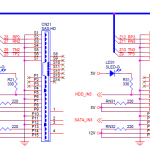

PCB DESIGN

Print circuit board (PCB) design service options ensure your design needs are addressed efficiently and professionally. Services available meet your needs by providing flexible options for prototypes whether new or existing. Experts provide the support your design needs by assessing and evaluating your interests. Services provided assist with develop of applications including consumer electronics of high volume and multi-gigabit solutions. Designs created for applications come from hand drawings or digital concepts with desired measurement components. These designs ensure customers get the results they want with the performance they need.

Goto PCB DESIGN→

DIE CASTING

Die casting is a detailed process providing customization to metal materials. The process includes pouring melted metal elements into molds made of steel. The molds help set the material into a solid metal or parts. There are different types of dies, aka molds used based on the type of raw material used in the process to create the mold. Die casting is a prime manufacturing process used to create distinguished metal parts with smooth or sharp edges.While the process offers options for creating customized parts or pieces for equipment needs, it is a cost-effective option when parts are needed in bulk or require mass production.

When using raw materials, the process makes it easy for product parts to be created meeting specific dimensions, angles, and other essential features. Casting allows for any shape to be created while including elements that ensure the process is completed correctly. Die casting also allows for parts to be joined together if the assembly is needed. The process helps metals gain higher toleration levels making a strong and finished part. Scrape materials are minimized, and production of many types of parts is completed quickly and thoroughly thanks to technology advancements assisting in the regulation of the casting process.

Goto DIE CASTING→

LASER CUTTING

Laser cutting is a cutting process that can be used to cut different thicknesses of metal and non-metal materials.

The polymerized laser beam is the basis of this technology. After the laser hits the material accurately, the material is heated to melt or evaporate to achieve the cutting purpose

CNC

Precise process to make your product better

MOCK UP

Cut the sample validation time

3D PRINTING

3D printing is the construction of a three-dimensional object from a CAD model or a digital 3D model.

It can be done in a variety of processes in which material is deposited, joined or solidified under computer control,with the material being added together (such as plastics, liquids or powder grains being fused), typically layer by layer.

Most of the material:

- PLA.

- Tough PLA.

- ABS.

- METALS

- Carbon

- Nylon

- TPE.

Use 3D printing will help to validate the design faster than Rapid prototyping of some small parts

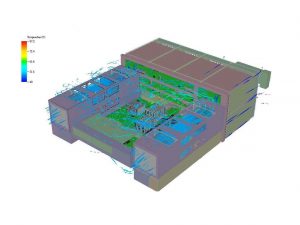

THERMAL SIMULATION

Faster way to check the design closely to the actual prototype

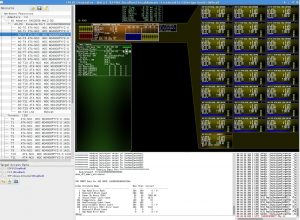

CRC TESTING

Precise process to make your product better

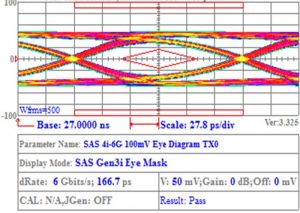

EYE DIAGRAM

Make sure the accuracy of signal Integrity

CABLE SERIES

The power supply and high-speed cable design you need

- SFF-8654 Series

- SFF-8654 Bifurcation

- SFF-8643 Series

- SFF-8643 Bifurcation

- SFF-8611 / SFF-8482

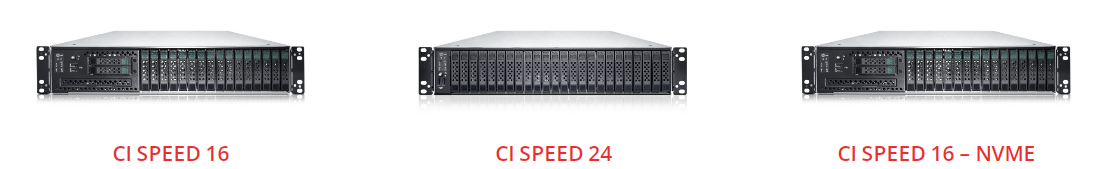

SPECIAL ORDER

Ordering Ci Design’s standard products (Server, Tower, Storage, DAS……) allows you to meet your end customer’s needs faster.

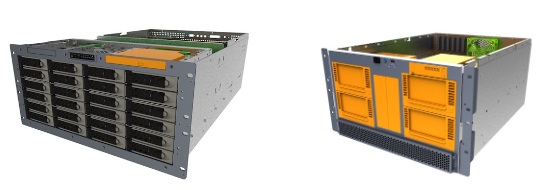

4U 60 BAYS

2U 48 BAYS

OCP

U.3 NVME