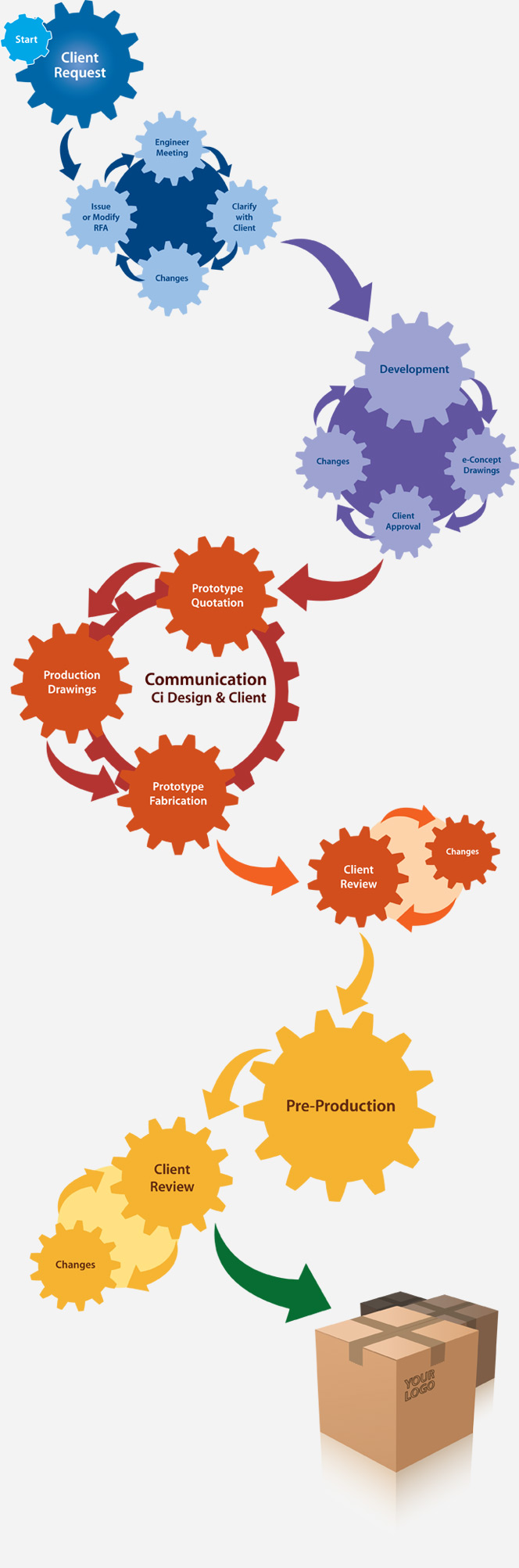

The Design Process

Phase 1:

Concept Development

- Client Request

Our highly-trained technical sales specialists and engineers chat with you about your idea - Issue or Modify RFA

RFA (“Request For Action”) process begins - Engineer Meeting

Meet with Ci Design Engineers to discuss client specifications and iron out any design and technical issues - Clarify with Client

Our specialists explain any issues with you - Changes

Modify the specifications as necessary until final design is ready for development

Phase 2:

Product Development

- Development

Our experienced engineers analyze the completed design and begin development - e-Concept Drawings

The e-Concept design is turned into 2D and 3D drawings, and digital mockups and prototypes are generated for review - Client Approval

You review the e-Concept Drawings and either approve them for Prototyping, or request additional changes to the design - Changes

The design is modified and re-cycles through the Development Phase

Phase 3:

Prototype & Fabrication

- Prototype Quotation

- Production Drawings

Concept drawings are finalized for production - Prototype Fabrication

- Clarify with Client

Our specialists explain any issues with you - Client Review

We send you the prototype for review - Changes

Any modifications to the design are added, and the design re-cycles through Development and Prototype Phases

Phase 4:

Pre-Production

- Pre-Production

- Client Review

- Changes

Any modifications to the design are added, and the design re-cycles

Phase 5:

Production

- Production

- Post-Production Support

- Document Control & Backups

All files and procedures are documented and backed up for future orders from client, or for client’s future reference.