Branding

Customization

Ci Design offers several branding services to give your product a unique identity and presence in the market. Consider:

- Materials & Styles

- Logo & Labeling

- Faceplate Bezel Design

- Custom Packaging Solutions

- We take both small and large volume orders depending on specifications

Industry Solutions

Consistent With Your Brand

Bring us your ideas, and we’ll create a solution that sticks to your styles and your company image. We offer a wide range of branding options to help you establish a unique presence in your industry, including:

- Metallic materials such as aluminum, sheet metal, stainless steel, and titanium

- High-quality plastics such as acrylic and fiberglass

- Brushed and polished finishes

- Several painting options, from Liquid Wet Paints to Powder Coating, customized specifically to your Pantone colors

- Special adhesives, pressure-sensitive labeling & tagging options

- Silk Screening, Engraving, & Pad Printing

- Aesthetic flexibility and an experienced design team to help you customize your Faceplate Bezel

Design From Start To Finish

Our specialists have you covered from start to finish, including covering mechanical design, electrical design, and several other services for your custom project.

Design Services

- From Concept to Completion

- Tooling Design & Manufacturing

- Customized Mechanical Products

- Plastic Molding & Injection

- Pressure Die Casting

- Rapid Prototyping

- Advanced Digital Prototyping

- Adherence to Safety Agency Policies & EMI Considerations during Design Process

Cost-Effectiveness with Advanced Digital Prototyping

Ci Design Engineers work closely with clients to create accurate and valid drawings of each OEM & ODM project. We help you visualize your pre-production product using the latest, high-end 3D engineering software available.

- 3D Sample Drawings

3D sample drawings are generated during the Product Development Phase, and interactive, 3D-animated digital mockups are completed for client review. - 3D Renders

To give an even more realistic impression of what the product will look like, we also provide hyper-realistic 3D renders of each product. - Get a realistic impression before Fabrication and Production

Digital Prototyping is so accurate, it’s able to give you a realistic impression of how your product looks, works, and feels at a fraction of the cost. We’ll help you finalize your design to perfection before ordering the physical prototype.

Your Choice of

Materials, Colors, & Styles

Along with custom labeling options, Ci Design can customize your unit to reflect the materials, colors, and styles that identify your specific brand.

Metals

Aluminum

Brass

Bronze

Cold Rolled Steel

Copper

Galvanized Steel

High Strength, Low Alloy, Steel

Hot Rolled Steel

Sheet Metal

Spring Steel

Stainless Steel

Sterling Silver

Teflon

Titanium

Zinc

Other Materials

ABS

Acetal

Acrylic

Carbon Fiber

Fiberglass

Nylon

Plastic

Polycarbonate

Polystyrene

PVC (Polyvinyl Chloride)

Customize Your Own Styles

At Ci Design, we know that branding is more than just a logo on a faceplate – it’s the aesthetics and overall feel of the product that fill in the rest of the picture.

To support this level of customization, we offer an array of tools and capabilities for your convenience:

Manufacturing

- Aluminum Casting & Extrusion

- Brazing

Removing material from metallic strips or blank areas. - Embossing

Raised, sunken, or relief designs & patterns. - Metal Blanking

Punching, cutting, or shearing stock metal materials, usually in preparation for additional design processes. - Metal Stamping

Forming strip or sheet metals using extreme pressure. - Notching

Removing material from metallic strips or blank areas. - Press Braking

Bending, blanking, corrugating, curling, notching, perforating, piercing, or punching metals. - Punching

Forming metal components. - Roll Forming

Creating shapes and contours. - Shearing

Cutting metals. - Welding

Joining metals, including grinding, polishing, filling voids, preparation and priming for painting or other designs processes.

Paints

-

- Liquid Wet Paint

- Electrochromic Paint

- Latex Paint

- Oxidative Cure Coatings

- UV Curing Paints

Powder Coating

-

- Epoxy

Tough, chemically resistant material. - Hybrid

Similar to epoxies, with some UV and overbake advantages. - Polyurethane

Polyester Urethane, exterior durable, thin film. - Acrylic

Durable and resistant material. - PVDF

Polyvinylidene Flouride, or “Kynar” – highly-durable commercial resin.

- Epoxy

Plastics

-

- Injection Molding

- Vacuum Forming

- Thermo Forming

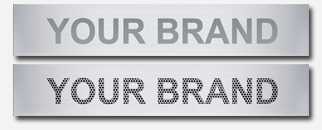

Logo & Labeling

Emphasize your brand with several labeling and tagging options. Below are just some of the possibilities we offer.

To find out more about our branding capabilities, please call 1-800-576-5487.

Adhesives

- Co-Adhesive

- Emulsion Acrylic

- Heat Seal

- Hot Melt

- Linerless Construction

- Solvent

Top Coating

- Laminations, TT, Laser, & UV

- UV Inks & Varnishes

Sticker Labels

- Epoxy Stickers

- Embossed Stickers

- Magnetic Stickers

- Vinyl Stickers

Bevelling & Embossing

- Flush Designs

- Intrusions

- Impressions

Face Materials

- Color Materials

- Embossed Laminates

- Flexible Vinyl

- Frosty Clear Vinyl

- Gloss/Semi-Gloss

- Laser Printable Brown Kraft

- Polyester

- Prolypropylene

- Reverse Coated Foil

- Tyvek

- Valeron

- Wine Papers

Applications

Silk Screening

Recommended for medium- to large-volume orders.

- Matte Powder Coating

- Anodized Aluminum with Fine Brushing

- Injection Molding with Matte Finish

- Print on plastic, metal, and glass

Engraving

Ideal for small-volume orders.

Pad Printing

Recommended for small print areas.

Metal & Plastic Tagging

- Aluminum Tags

- Blank Metal Tags

- Brass Tags

- Danger Tags

- Embossed Metal Tags

- Engraved Metal Tags

- Marked Metal Tags

- Metal Rim Tags

- Paper/Tyvek Tags

- Plastic Engraved Tags

- Self Laminated Tags

- Stamped Metal Tags

- Stainless Steel Tags

- Write on Tags

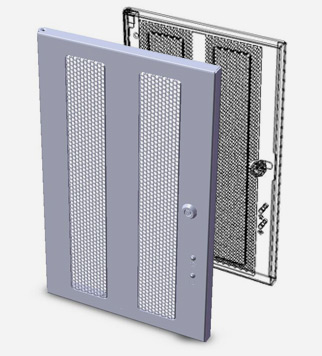

Customize Your Faceplate Bezel

Whether it’s a server chassis or storage chassis, or a design that’s completely unique to your brand, we offer some of the highest quality Faceplate Bezel design and manufacturing services available.

Choose Your Materials

Create a unique look for your unit starting from the materials. Some popular choices include:

- Anodized Aluminum

- Stainless Steel

- Vinyl Overlays

- Plastic Molding

Create A User Interface

- Design an LCD User Interface

- Add LED Light Indicators

- Silkscreen a Menu

Add Your Logo

Using our wide array of Logo & Labeling options, apply your logo to the unit and customize to emphasize your brand.

Aesthetic Flexibility

Change the cosmetic appearance of your unit, mixing colors, branding techniques, and more.

- Paint it in your colors

- Silkscreen or stamp your logo, or even apply it with a special adhesive

- Create shapes and designs that work with your brand

Custom Packaging Services

Ci Design offers several package design services to give your product a unique identity and presence in the market

It Comes With Your Name On It

- Customized to include your logo, brand, or style

- Flexible Structural Design

- Flexible Graphic Design

Industrial Packaging

- Bulk Containers, any grade

- Triple Walls or Laminated Walls

- Single or Double Box Packaging

- 1U-8U Packaging Solutions

(and higher, depending on specs) - Cluster Cabinet Packaging Crates

- Pre-assembly & Post-assembly

- Corrugated with Wood Supports

Regular Slotted Container Boxes (RSC)

RSC’s are perfect for product shipping, protecting against damage during transportation.

- Full Overlap Cartons

- Multi-Panel Wraps

- Telescopting Boxes

- Regular Slotted Cartons

- RSC with Variable Flaps

- Half-Slotted Box with Cover

- Double Cover

Packaging Accessories

Add extra protection to your products during shipping, customized specifically to your specifications.

- Box Dividers

- Corrugated Trays

- Corrugated Pads

- Custom Foam Inserts

Custom Product Packaging

Ci Design has the ability to create custom product packaging designed specifically to highlight your brand and your style. Some examples of our services include:

- Die-Cut Boxes

- Ballot Boxes

- Mailers

- Gift Boxes

- Bin Boxes

- Suitcase Boxes

- Cutout Wraps

- Specialty Boxes

- Folding Cartons

- Setup Boxes

- Telescopting Boxes

- Wooden Boxes

- Graphics Packaging

- Litho Label Lamination

- Single-Face Lamination

- Multicolor Direct Printing

- UV Coating

- Conceptual Designs, Renders, and Physical & Digital Mockups

Solutions for Established Providers & Industry Entrepreneurs

Our 25+ years of experience is available to help you build your solution, every step of the way.

- Consult with Tried and True OEM & ODM Specialists

- Build on your ideas

- Verify and Validate designs

- Send your ideas to production

- Follow our OEM & ODM Process Model

Project Management

- Support for both large- and small-scale projects

- Achieving results Quickly and Efficiently

- Controlled use of Budget and Resources

- Constant Communication via Open Contact Window for the duration of each project

- Design & Revision Control

Manufacturing

We have several international manufacturing centers, totaling over 20,000 square feet of top-of-the-line facilities to handle virtually any volume of production our clients may anticipate. Our Production Team is supported by advanced 3D engineering software, detailing every aspect of each manufacturing project to ensure high quality, error-free results. Each product endures thorough testing, from the drawing board to the final delivery.

Order Management, Configuration, & Logistics Support

We don’t just focus on the manufacturing side of our projects — we take it a step further:

- Continued post-sales support

- Streamlined production procedures, minimizing the time-to-market phase

- Customer service satisfaction

- Satisfaction with the final product

- Access to fully-trained technical support team

A Dedicated Team

That’s Got You Covered

On behalf of our valued customers, our OEM & ODM services comes with a dedicated OEM account management team, including project managers, fully-trained technical systems specialists, engineers, OEM & ODM solutions consultants, customer service professionals, and a tried-and-true experienced technical support team.

Get your Free Consultation to find out more

about how we can help you turn your ideas into reality.

Compliance with Quality Standards

Ci Design is an ISO QMS 9001:2008 certified manufacturer with a commitment to higher quality and customer satisfaction. We are proud to be one of the leading innovators of the design, development, manufacturing, and integration of over 1,000 OEM & ODM computer server and storage system solutions with more than 25 years of experience.

Warranty & Repair Services

In line with our mission to provide the best quality service to our valued customers, Ci Design sports a standard 3-Year Manufacturer Warranty program to ensure the highest level of customer satisfaction after the final delivery of each project. Our dedicated Technical Support Team is here to help you:

- Analyze hardware or software system failure

- Provide warranty replacement services

- Offer refurbishment and repair of Ci Design Products

- Support you with system upgrades

- Provide technical services tailored to your specific business needs